Droneport

The Droneport project to overcome the challenges of the future

“The Droneport project explores the potential of an ‘infrastructural leap’ using cutting edge technology to surmount the challenges of the future.”

Lord Norman Foster

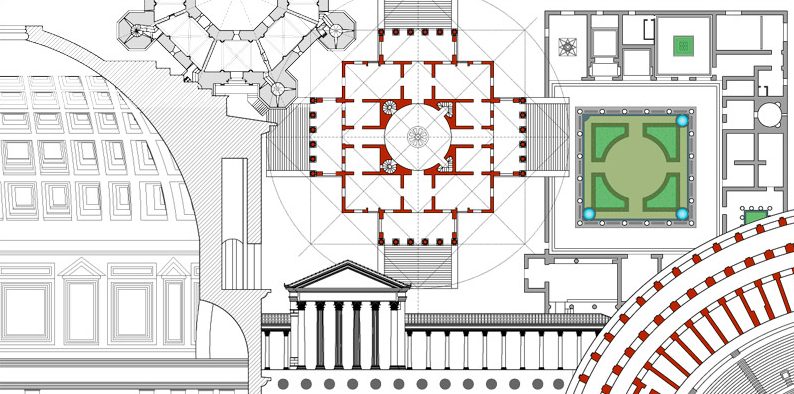

Historical Background

In the African continent where only one-third of the population lives around 2 km from the road. There are no major ways of transport such as railroads and motorways, only tunnels and bridges for the easy movement of freight. As per current conditions, the population is expected to double by 2050 [Foster, 2016]. So, cope-up with such demand with an efficient infrastructure would be nearly impossible.

However, with the technological advancement achieved; Jonathan Ledgard, who is a writer and teacher at EPFL (Lausanne, Switzerland) has thought of a remarkable idea of establishing a drone network route in Africa.

In a paper entitled “Better use of the lower sky in a sharing economy” Ledgard put out these plans to set up Africa’s first commercial drone cargo routes. it will be 80 km long and covers several villages and towns. Initially, drones will carry smaller payloads such as necessary medical supplies and later on they will evolve into heavier crafts that can lift about 20 kgs or more at once.

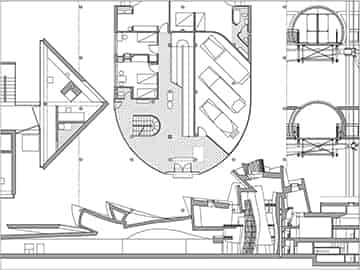

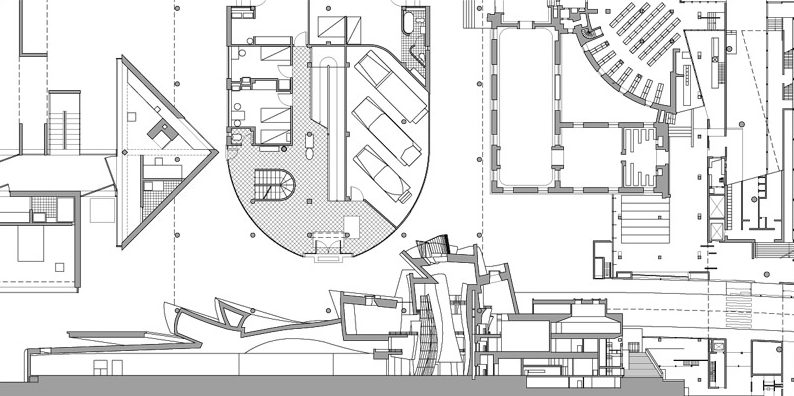

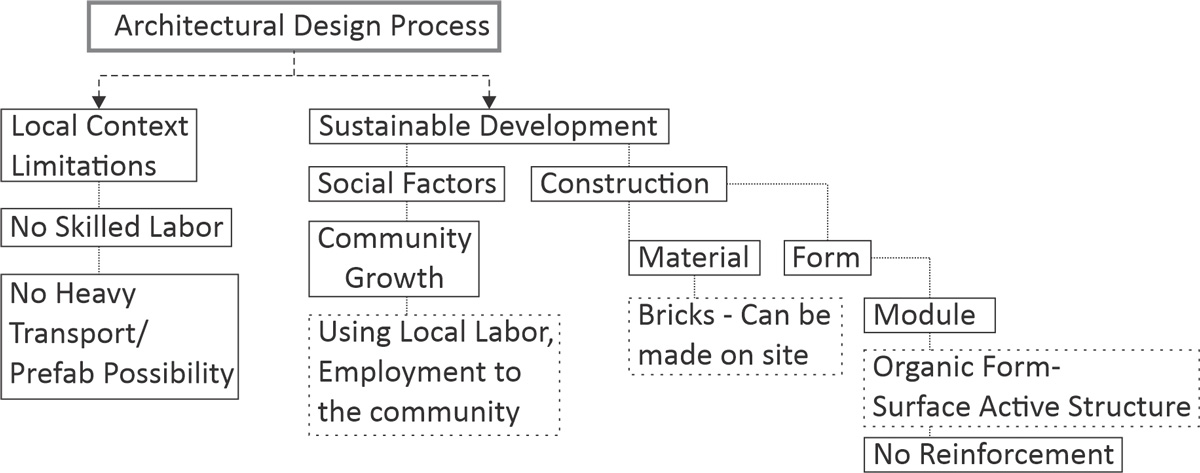

Architectural Design Process

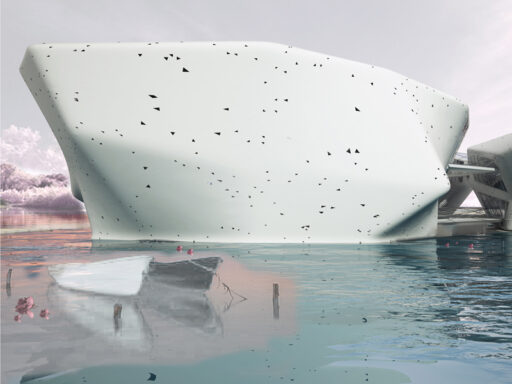

The Project should be simple, inexpensive, built locally and able to withstand fluctuations in the climate also beautiful.

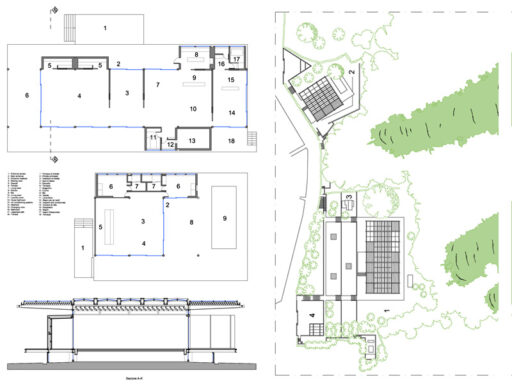

The initial objective was to establish a hub for drones, they cannot be just operated from a shipping container. So, the idea of modular built-forms developed which should be possible to be constructed by local communities. As there is a demand for local employment and context doesn’t allow foreign development where all construction happens outside and assembled on site. There are also social factors inducing the design process. Africa comes under a developing nation and there is a huge demand for employment. So, the project should also provide the employment to the community. Therefore, method of construction, form, characteristics of modulation were the important constraints.

Architectural Design Process. Image of the author

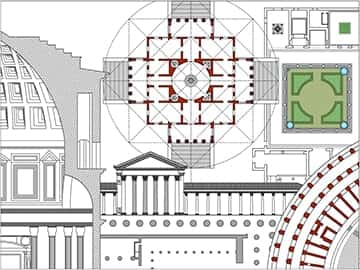

Conceptual Sketch by Lord Norman Foster. Image: Courtesy of the Norman Foster Foundation

Lord Foster has ambitious plans for this project, it will start as an airport for drones but it will evolve. As the technology will evolve the form of the space and functions will also evolve. These modules will serve the community as civic centers, clinics etc. the form of the structure gives the possibility to use it in many ways. This made the Droneport project, became a sensitive project planned for very local conditions where the locals will be benefitted from globalization.

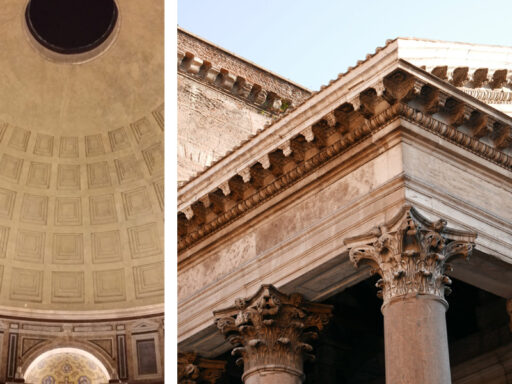

The final result after considering all the factors was a ‘Brick Vault’ where 92% of the material will be the ‘Ground Soil’.

Construction Analysis

The research will briefly look into; Form optimization, Material Specifications and the Method of Construction.

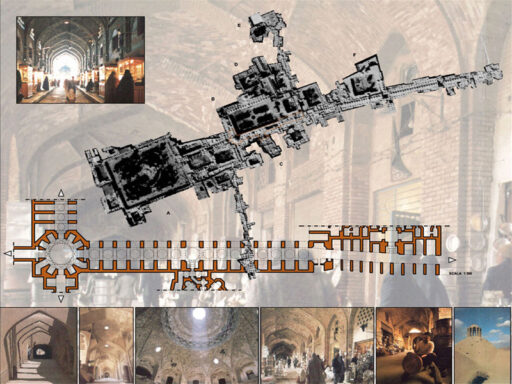

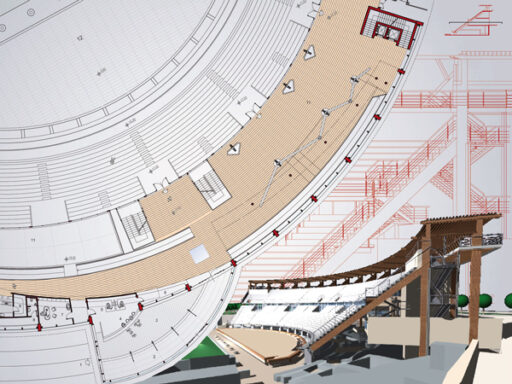

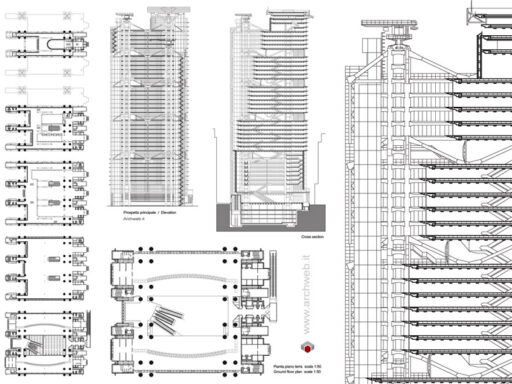

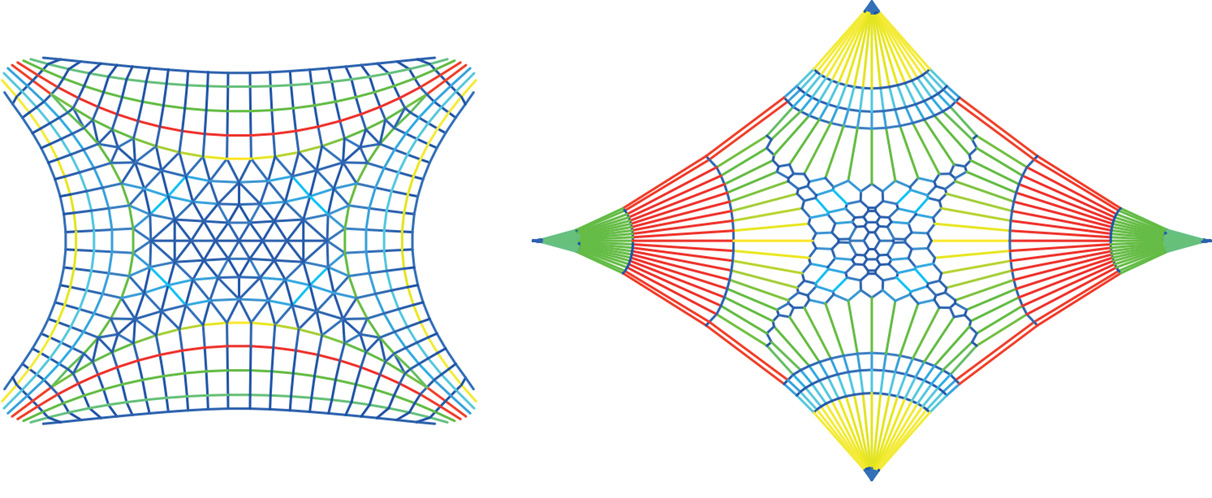

The ‘Brick Vault’ further optimized by ODB Engineering, a practice established by Philippe Block, Dejong and John Ochsendorf. It has been done by ‘RhinoVault’ gives a form which would be in pure compression based on thrust network analysis so there will not be any need of reinforcement in it.

On the left diagram of the reciprocal form. On the right, diagram of the forces.

Images by Norman Foster Foundation

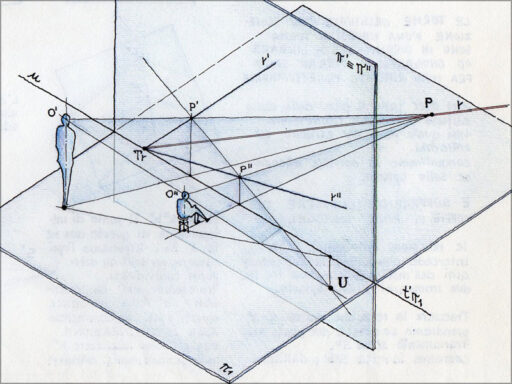

In the above diagram, the mesh network establishes with Nodes, Edges and Polygons are presented here with different colours. This generated the idea of three-dimensional thrust network analysis, which later on established by Phillipe Block from ‘Block Research Group’. It is graphic statics in three dimensional with an interactive interface.

In basic terms, RhinoVault (an interactive Rhinoceros 3D Plugin) developed by Block Research Group – generate funicular compression-only geometries. Until all the tension values turn zero, the form needs to be optimized and, in the end, you derive a form that is in total compression and can be constructed using masonry without reinforcement.

However, while using this tool, basic geometry should be in the head to achieve the final form. It can only optimize and gives you a funicular form.

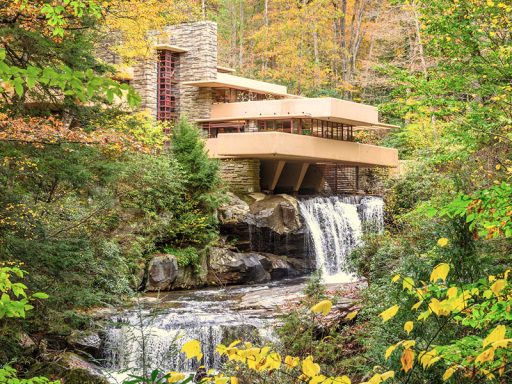

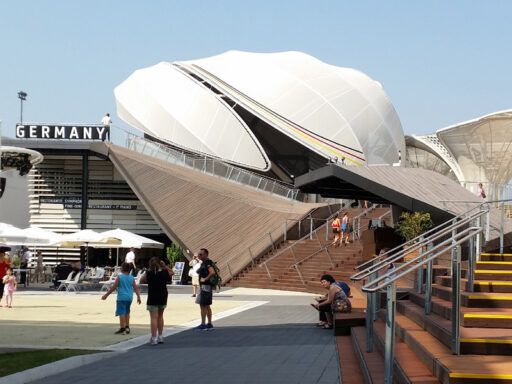

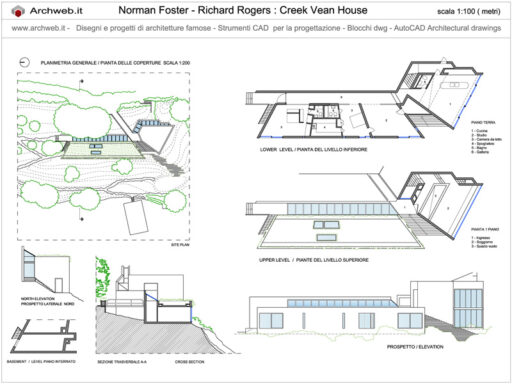

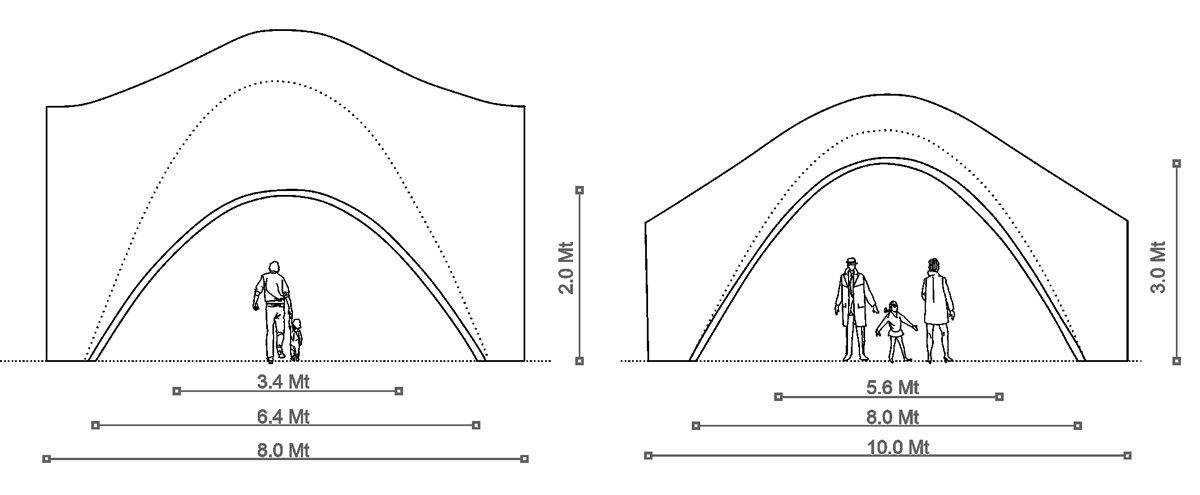

This picture shows the basic elevations of the prototype of Droneport. To demonstrate the feasibility of the project, it was decided to construct a prototype on a 1:1 scale at ‘Venice Biennale -2016’. The Structure was constructed by Students from the surrounding institutes with the help of skilled masons. This proved that the Catalan Vaulting Construction technique can easily be taught to the local community in the real scenario.

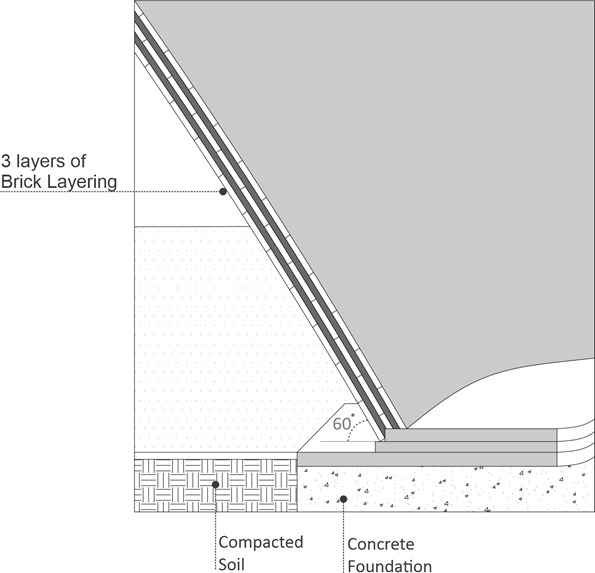

The structure’s base is an orthogonal grid, it is open from all four sides giving enough space for all required functions. The peculiarity of tile vaults is they do not require any kind of heavy formwork in the traditional way of building. But looking at the form generated, the geometry of the form has to be right to work under structural load transfer without any failures.

It does not have any kind of reinforcement only four RCC supports at the end, which is important as the generated thrust will be transferred to the ground by that. It is very important to remember that the tolerance of such masonry shell vault is very low so even 5-7 mm can cause deadly failures. There is hardly any formwork but Guides. These guides can be in form of rebar or plywood etc. to make sure that, the shape is going in the right direction as optimized by the calculations of load transfer. In Africa, where the project is conceptualized; the locals can use even wooden formwork (for the arches) and scaffolding to construct the vaults.

LafargeHolcim Foundation played a major role in the construction process, they have innovated a brick tile, ‘DuraBric’ with the strength of a brick. It was specifically designed for the ‘Droneport’ project where the aim was to erect a structure that will be economically and socially viable as well as the costs would be a determining factor.

Construction Process

1. Firstly, put out the scaffolding as per the form of the structure.

2. The four arches, as per the guides and use of minimal formwork has to be constructed.

3. Later on, brickwork from all the edges of the arches can start horizontally or in a herringbone pattern.

4. Consequently, after the first layer of brick tiles laid out, the remaining layers can proceed with mortar.

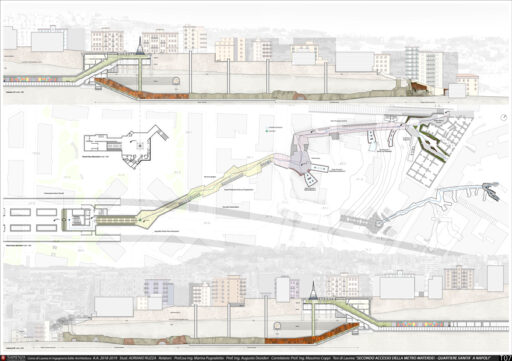

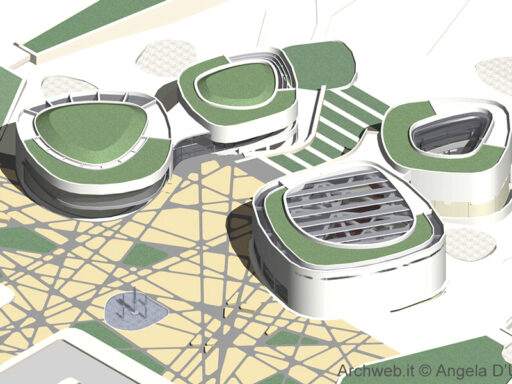

Modularity and Repetition

‘Droneport’ Project envisioned establishing a network of drones throughout Africa. although the project does not end there; it can be a civic center, a dispensary or even a marketplace.

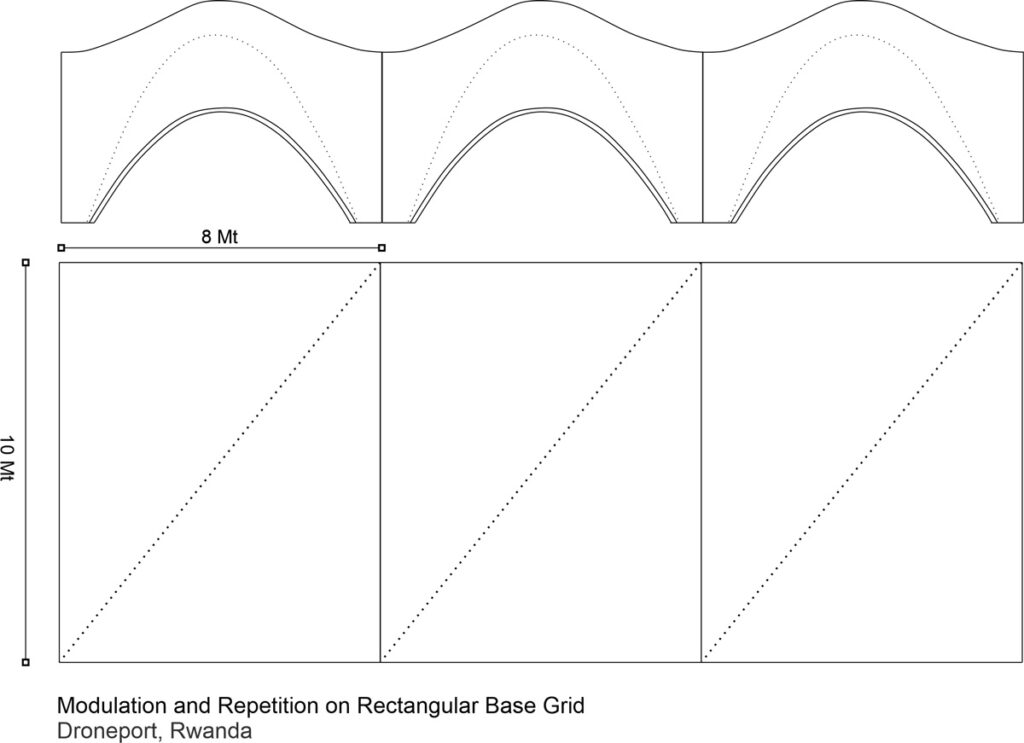

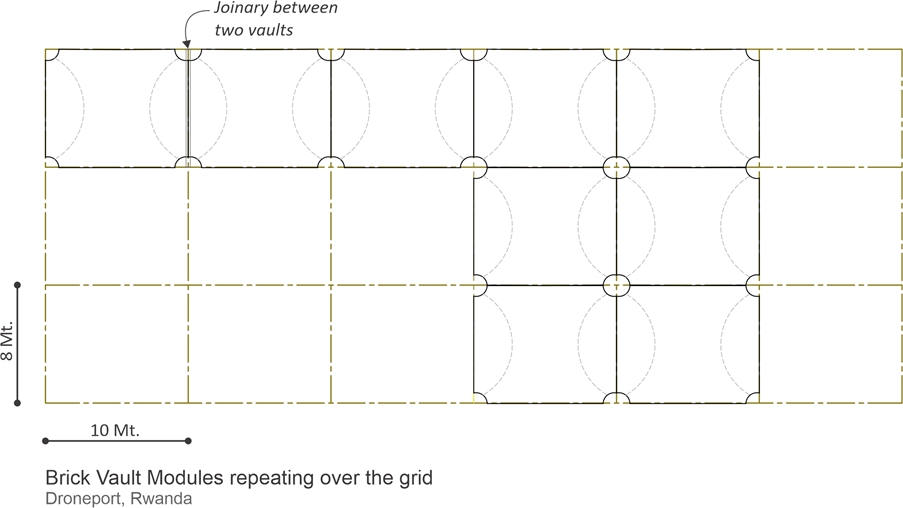

The idea is to define a ‘module’ and then repeat it over the necessary grid require to fulfil the functional aspects of the project. Currently, the prototype is above mentioned in Figure (42) is an 8×10 Mt. module which repeated about 7-10 times in a row to create enough space to function for an airport. However, the possibility suggests that; it will change as per the requirement. The structural innovations in future may suggest a bigger module, and the grid can expand in both the direction. Even rather than keeping singular volume, the volume may differ as per the different functions being housed in the building.

The Prototype has spoken that, this traditional technique with the use of technological advancement can solve the ‘Infrastructure leap’ of Africa. The prototype was dismantled in 2019.

The project is in motion in Rwanda and three Droneport will be completed by 2020, covering almost half of Rwanda.

Aftermath

The LVC (Lake Victoria Challenge 2018) held in Mwanza, Tanzania was the first-ever international symposium on drones in Africa and the world bank estimated about 130 Billion USD infrastructure demand in Africa. Three Droneport was supposed to be completed by 2020, covering almost half of Rwanda. However, as of 2021, there is no update on the actual timeline of the project. Supposedly due to the current COVID pandemic and existing political conditions the project might have been delayed.

Cover photo: Foster + Partners