Outdoor flooring: how to choose?

Functionality, aesthetics and durability of the material.

In order to make the best choice of outdoor flooring, whether private or public, it is extremely important to remember that it has the capacity to not only improve the aesthetics and enjoyment of places, but also to improve their liveability.

As with any construction element, for outdoor flooring we will take into account the functionality, durability and aesthetics of the material.

We will also have to consider the uses and lifestyles of those who will be living in those spaces, thus choosing those materials that best respond to the intended use. The ease of installation, drainage capacity and resistance to temperature changes will also influence the choice.

The main characteristics of good outdoor flooring

As with all building materials, outdoor flooring must also meet certain characteristics. This is to ensure safety, durability and aesthetic appeal of the final project.

The main characteristics for choosing a floor are:

- Waterproof and non-slip: fundamental in those cases where a terrace is designed, or near water (such as fountains or swimming pools);

- Antifreeze: an essential feature in cold climates, it prevents the floor from freezing in winter, thus preventing dangerous falls;

- Resistance to loads: outdoor floors must be able to withstand loads without becoming damaged;

- Resistance to stains and mould: this characteristic allows the floor to last over time. It also prevents a potentially dangerous slippery layer from forming on its surface.

- Design: the style chosen will make the project uniform and harmonious.

In the case of special projects with specific design and performance requirements, it must be verified that each material meets all the benchmarks according to European (EN) and international (ISO) standards.

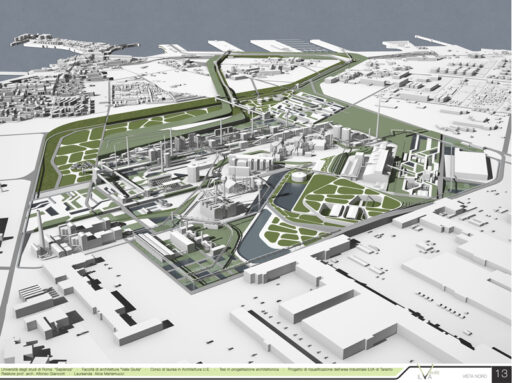

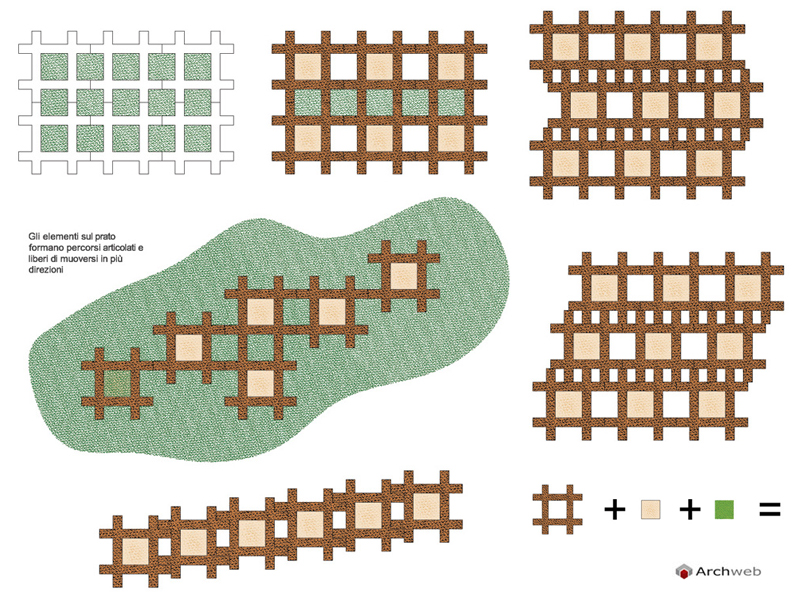

For example: in industrial areas, highly load-bearing and corrosion-resistant floors are more suitable. In commercial areas, highly draining pavements are preferable. In driveways, paving with increased thicknesses that can withstand loads is preferable. Finally, for green areas, removable and thinner pavements may be suitable.

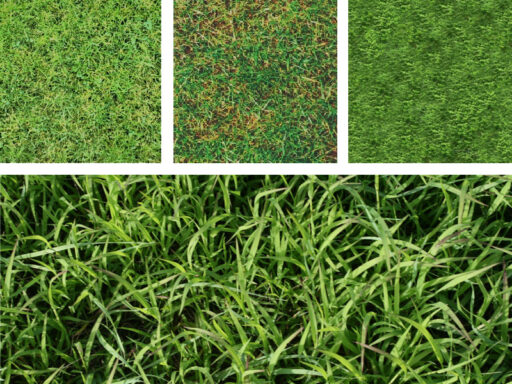

The most suitable materials for outdoor flooring

To facilitate the choice of outdoor flooring, the market offers an infinite variety of both natural and artificial materials each with their own characteristics and costs.

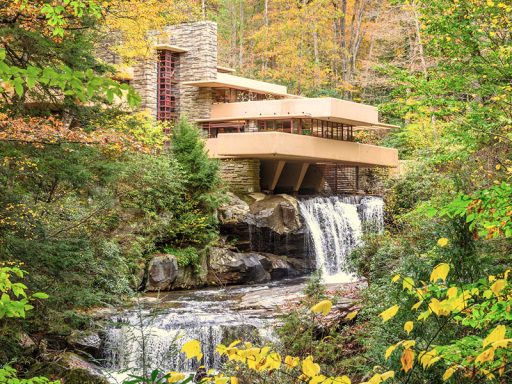

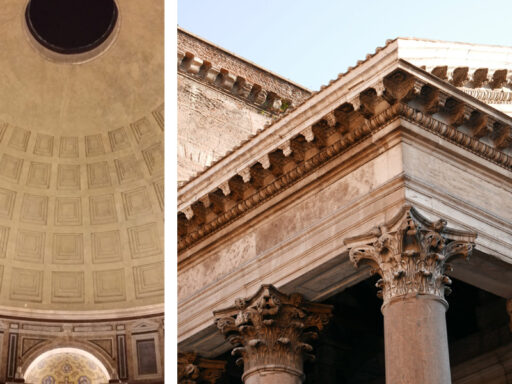

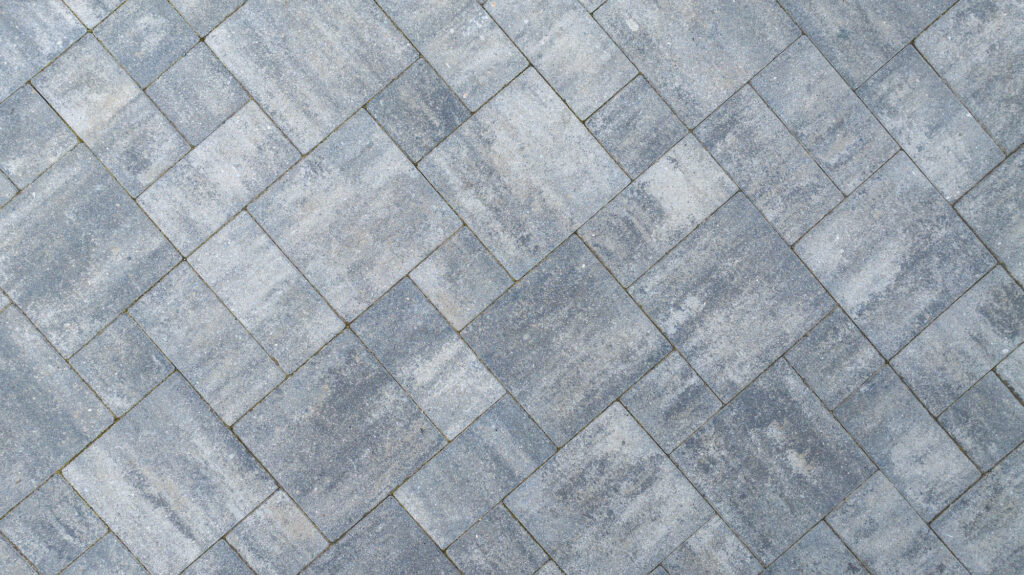

Stone and porphyry: material suitable for both private gardens and public exteriors. It has an infinite range of types and can be customised according to the cut and type of stone. This material is extremely resistant, non-slip (if not polished) and waterproof. While it requires little maintenance, it does require masonry work and specialised personnel for installation.

Wood: ideal for private exteriors, they come in the form of interlocking strips and do not require any work for laying. This type of flooring has a high cost and low resistance to humidity and weathering. They do, however, have a high aesthetic value and good load and impact resistance. (for more on interior wood flooring click here)

Rubber: mainly used around public areas for children. Rubber is very inexpensive, completely waterproof and wear-resistant. It is very easy to install as it often comes in the form of interlocking tiles (if you want to learn more about the interlocking system click here). Rubber flooring is also easy to wash and easy to lay, and is available on the market in numerous colours and patterns.

Vinyl: a low-cost material, often of little aesthetic value, it is completely waterproof, resistant to water, shocks and temperature changes. It can be found on the market in numerous colours and can be installed in a short time, even gluing it onto existing flooring.

Porcelain stoneware: outdoor porcelain tiles also enjoy high wear resistance, as well as being frost-resistant. They can be purchased in an infinite number of colours and finishes and glued onto existing floors.

Terracotta flooring: a valuable material mainly used for private exteriors. It is a handcrafted material, then treated with special waxes that make it resistant to mould and moisture.

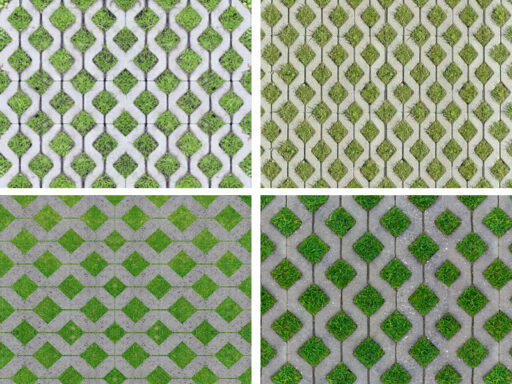

Concrete: very economical and quick to lay, it can be used to create very resistant floors that can be adapted to uneven surfaces. It can be coloured or reinforced, and if cast in situ, however, requires reinforcement with electro-welded mesh. It can be sold in the form of tiles that can be placed directly on the ground at no extra cost and without the need for specialised personnel. Concrete is a highly impact, mould and weather resistant material, as well as being non-slip.

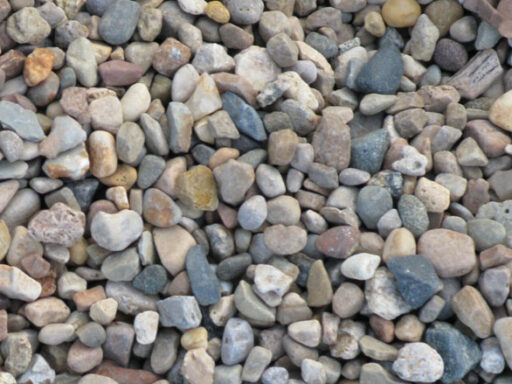

Gravel: paving used mainly for public parks, it is an extremely economical and non-slip choice. It does not require masonry work for installation. Its drainage capacity is linked to the drainage capacity of the ground on which it is laid. Gravels are not recommended in the vicinity of children’s play areas.

Pool and poolside gratings made of plastic or concrete are commercially available in the form of square modules often made of plastic, or also in the form of modular concrete modules. Grids are useful in those cases where a parking area needs to be created or, for example, as a bottom for inflatable pools. They do not require masonry work as they can be placed directly on the floor and have excellent impact and load resistance.

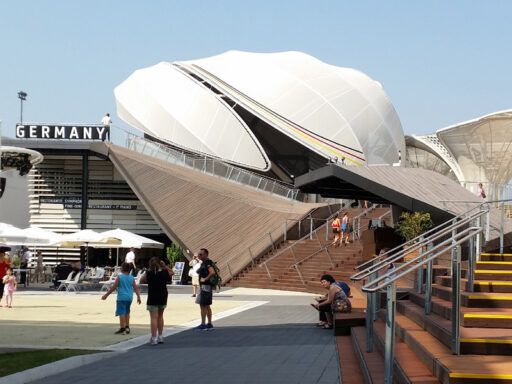

WPC (wood plastic composite) or wood composite: is an artificial wood. It reproduces the effect of wood and is extremely resistant to weathering, loads and impacts, as well as to chlorine and saline environments. This is why it is particularly suitable for outdoor use by the pool or the sea. It is easy to clean and maintain. It does not require specialised personnel for installation as it comes in the form of planks or square elements to be fitted.

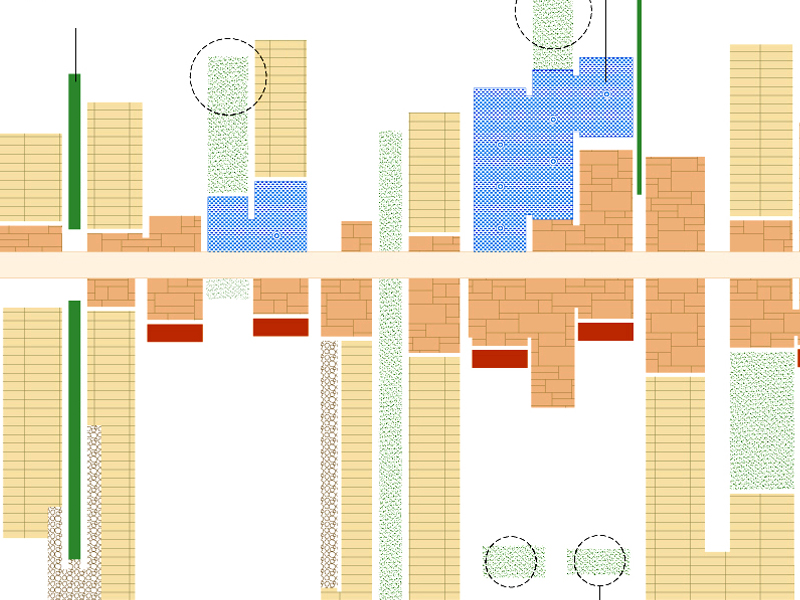

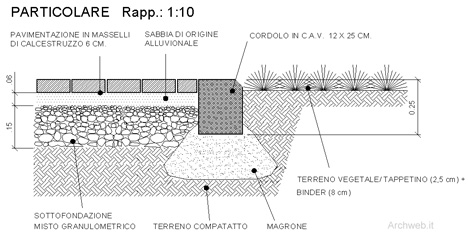

Laying outdoor flooring

When choosing outdoor flooring, it is essential to know how it is laid. Each type of paving has its own specific method. However, it is advisable to create a slope of approximately 2% to ensure a natural drainage of rainwater. This is to avoid stagnation that would pose a hazard, create stains, or give rise to infiltration in the case of paving on building roofs.

Laying in place: for all those elements such as WPC tiles, paving or gravel guards, wood and stone. The elements can be laid directly on grass, gravel, or on levelled (but also uneven) floors. This method does not require the use of specialised personnel or special precautions, other than an anti-fouling treatment to prevent the growth of weeds.

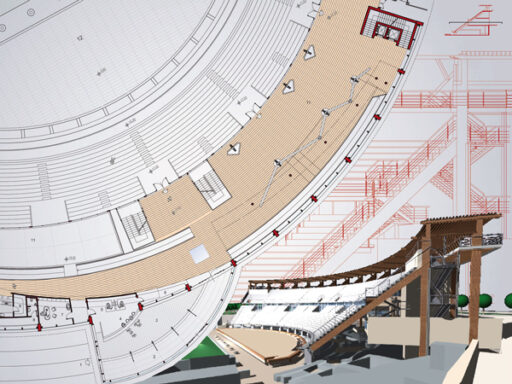

Screw laying: Floating floor coverings require the construction of a substructure on a levelled base, with special plastic pads on which the elements (wood, stoneware, WPC) can be laid. This solution requires specialised personnel and a levelled base. It gives the advantage of being a surface that can be inspected and is very resistant to temperature changes and highly draining.

Laying with glue: technique that can be used for rubbers and vinyls. It involves the preparation of a substrate and the use of adhesives. It can also be carried out on existing flooring, proving to be a fairly economical solution.

Recessed laying: a classic technique involving the use of cement-based compounds, making this technique economical despite requiring the use of specialised personnel.

Interlocking installation for self-locking floors: used for wood and rubber, it requires the elements to be placed on the ground and interlocked together. The installation is therefore easy and fast, proving to be the most economical choice for outdoor flooring.

The cover image is by Mikana Moments on pexels.com

The photos in the slide are by the respective authors on Depositphotos.com