Metal trusses: a construction tradition

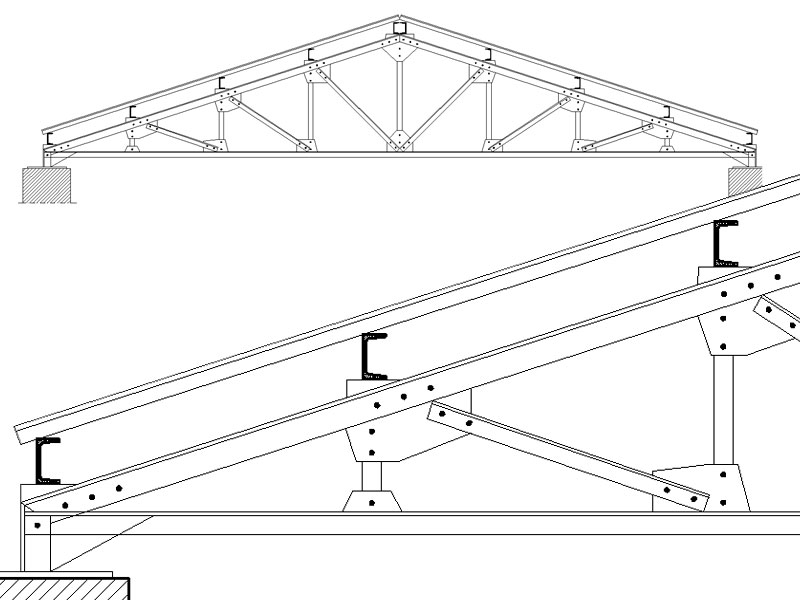

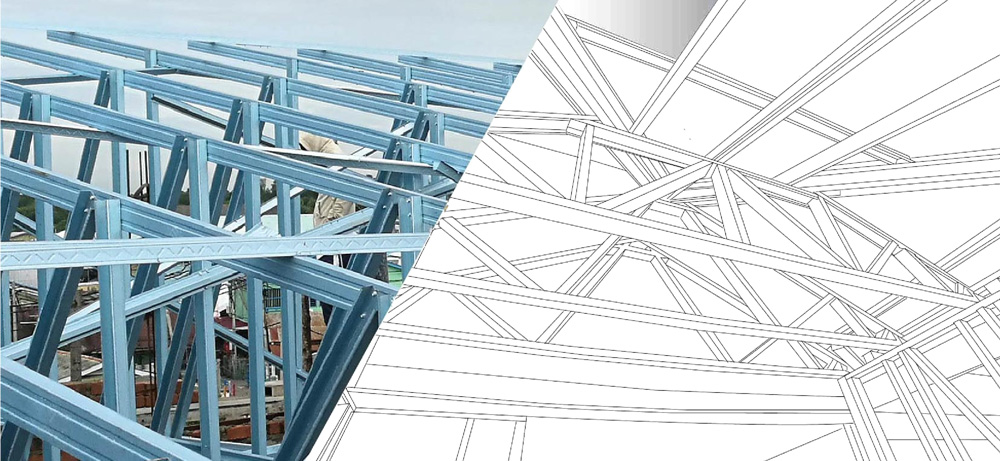

The metal trusses are a symbol of industrial architecture at the turn of the 20th century and ferry the wooden trusses towards the trusses

The metal truss is born from the wooden one through a process of specialization of the structural components.

Metal trusses, as a construction tradition, derive from wooden ones and developed in the 19th century, consistently with the spread of the use of cast iron and steel in the construction industry. In turn they give impetus to the development of steel trusses, which are also the result of calculation and construction science.

They are therefore a beautiful example of the historical evolution of a construction element with an elementary form which over the course of history has transformed in step with the availability of new construction materials and the refinement of the technique.

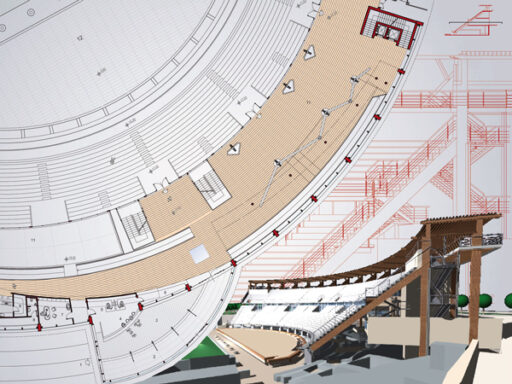

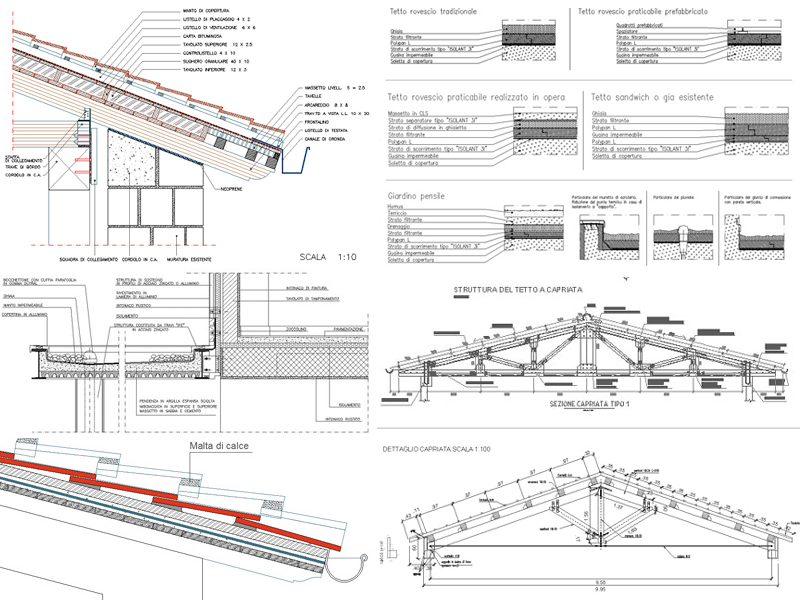

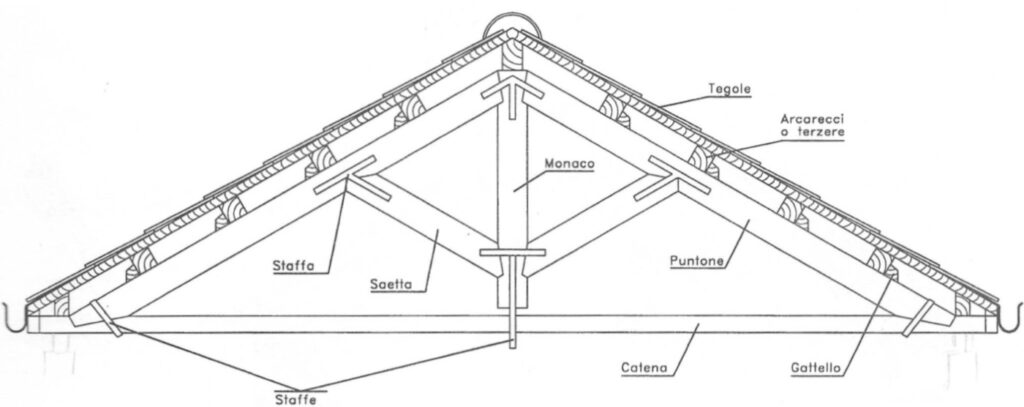

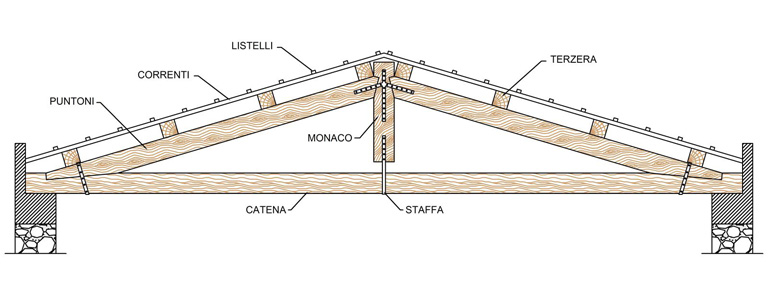

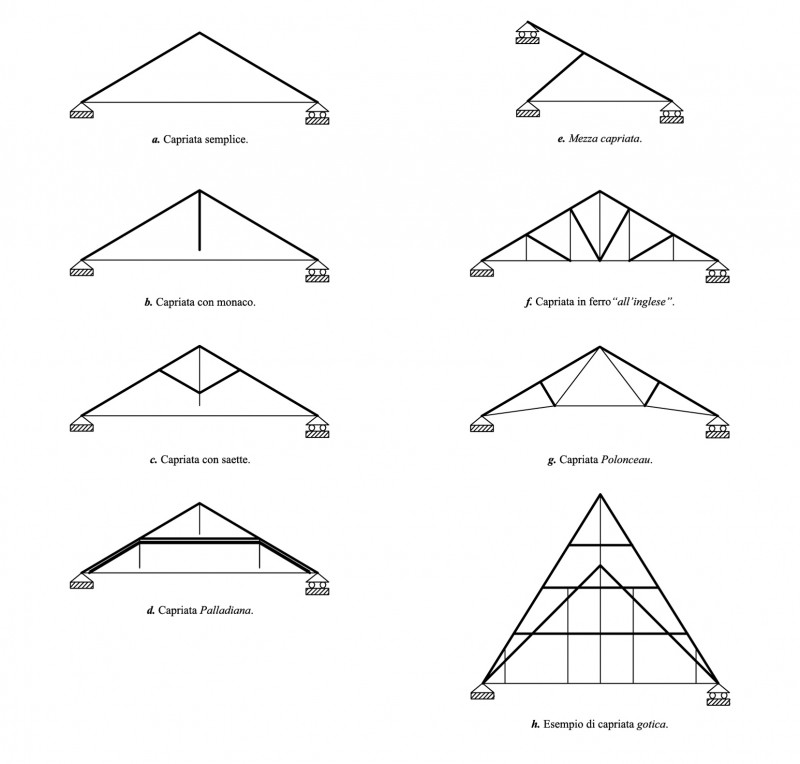

In general terms, the truss is that triangular-shaped structural element designed to constitute the main frame of the pitched roof; the secondary frame and therefore the roof covering are placed on it.

Source: R. Capomolla, S. Mornati, C. Vittori, S. Stucchi – Volte, solai, coperture – La Nuova Italia Scientifica – Roma 1995 – page 119

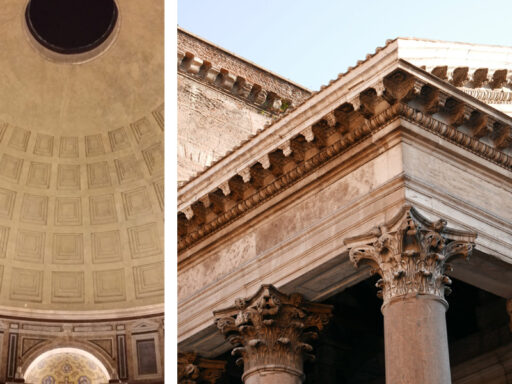

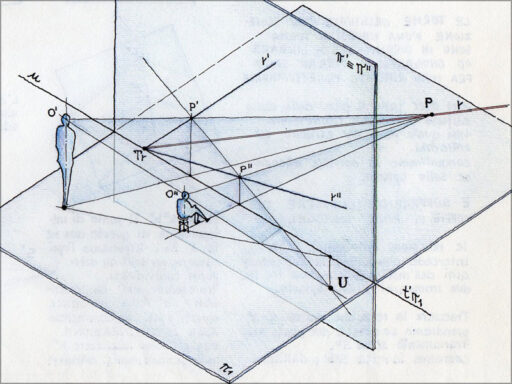

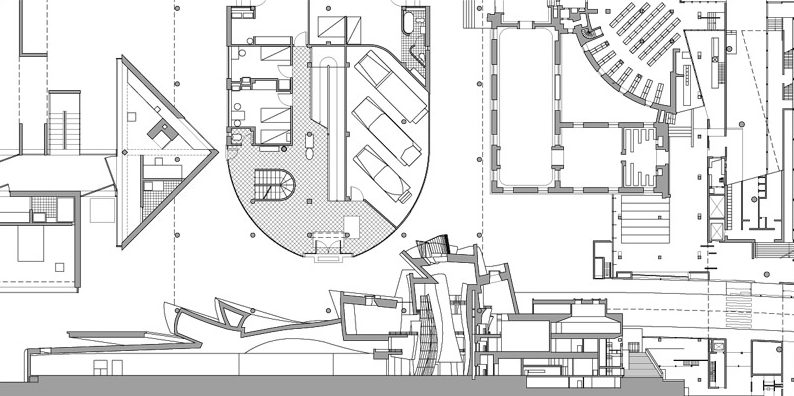

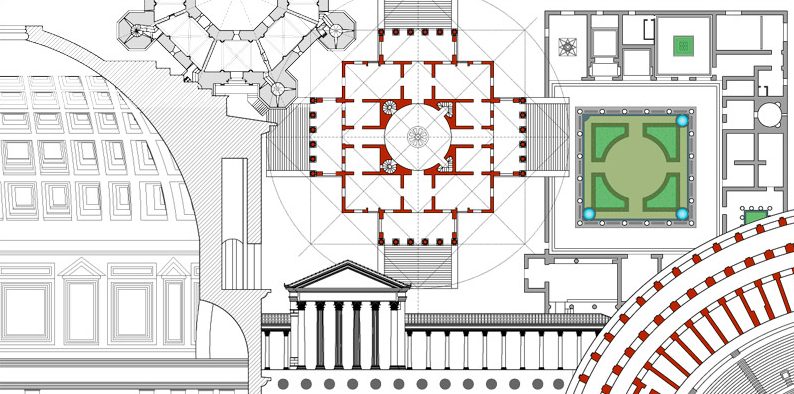

The idea of a hut, of two elements placed side by side that support each other by mutual contrast, resting or planted on the ground which supports its weight and absorbs its horizontal thrusts, represents an ancestral concept of shelter, of shelter from the rain. If it is not an archetype as old as man, we are close to it (we cannot forget about caves and dolmens), so much so that if we ask a child to draw a house, it is quite probable that we will obtain something similar to a square with a triangle on top.

It is precisely this scheme of the non-deformable triangle which over the centuries changes in materials, defines its structural concept and gradually streamlines its elements, until arriving at the metal trusses which mark a sort of terminus, from here we move on to the reticular structures composed of non-deformable triangular links, but no longer, or not necessarily, triangular in their perimeter shape.

Why is the triangle so important?

The triangle is a non-deformable structure. As long as we remain inside the triangle we speak of a truss, if there is a mesh of triangles we enter the realm of reticular trusses, if the triangle does not have a base (the chain) the horizontal forces are discharged on the supporting walls and we speak of scaffolding .

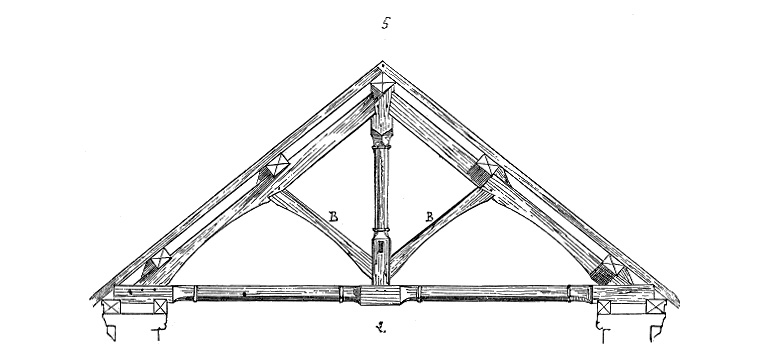

Simple wooden truss with monk and without arrows for spans from 5 to 7 m – click per scaricare il dwg

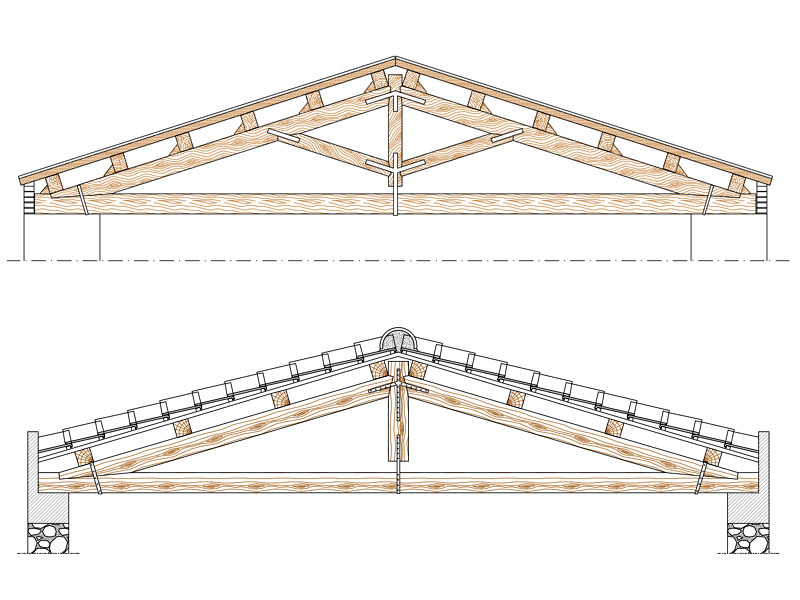

In the traditional wooden truss, the one formed by a chain, two struts and a monk, the latter does not divide the triangle in two, because it does not touch the chain, it serves to balance the struts and is stressed only by the slight traction of its own weight. If it weighed on the chain, it would have a load (in addition to its own weight), a greater deformation due to pressure bending (traction instead limits the bending of its own weight), the monk would work in compression and we would no longer have that perfect machine which is the truss normally defined as Italian, or Palladian, which in fact refers to the treatises of our late Renaissance. The French tradition, on the other hand, is different, influenced by and derived from the construction technique of the Gothic churches of the Middle Ages, but this does not mean that it distances itself from the evolution that will lead to steel structures.

French truss: compared to the Italian one, the monk and chain touch each other – Wikipedia

When the span to be covered expands (normally beyond 10-12 m), the Palladian truss becomes composite, because other elements intervene (bolts, double monk, counterchain, reinforcements on the struts, etc.), but always within the triangle main, without ever touching the chain and always with the aim of limiting the bending of the struts, or to make them with two shorter trunks instead of one long one.

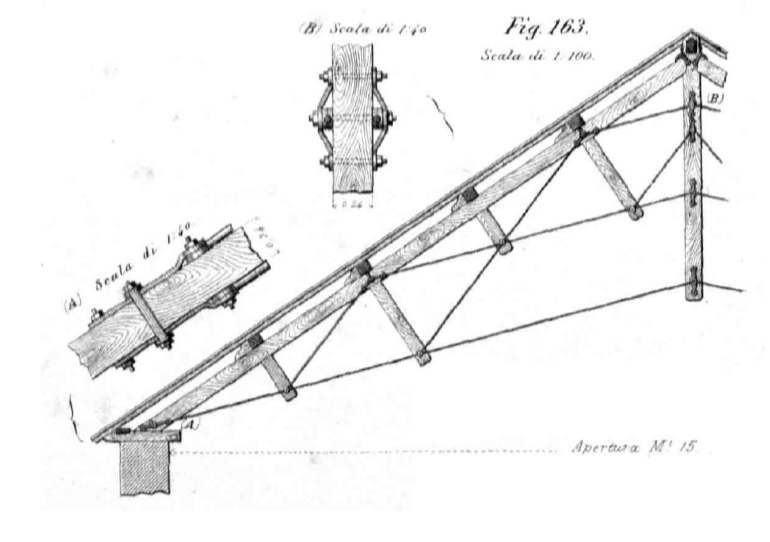

A detail to underline in the evolution from wood to iron of this structure is that the sections of the components of the wooden trusses are more or less all the same, regardless of the loads and stresses, to facilitate keying, i.e. the connections (dovetail , Jupiter’s dart, etc.) and the relative metal bracket.

It goes without saying that some elements are always oversized, especially the monk. This will change with the advent of steel and cast iron which are the products of calculation.

Even in its most basic form, the truss is an isostatic reticular structure that serves to discharge only vertical forces onto the structures that support it, itself absorbing the horizontal components derived from the load of the roof on the inclined elements.

If at first glance wooden trusses appear to be objects very distant from steel trusses, the typological evolution of metal trusses makes this boundary much more labile.

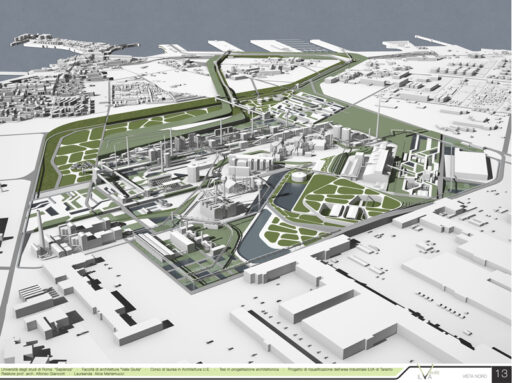

This proximity contributes to “confining” the development and diffusion of steel trusses within a rather defined historical context which begins with the industrial development of the second half of the 19th century and recently ends with the transition to covering industrial warehouses with flat structures ( metal lattice beams, pre-stressed reinforced concrete, laminated wood, etc.).

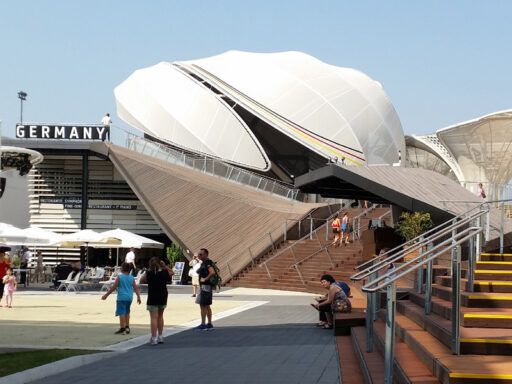

This does not mean that they are construction elements now disused or out of fashion, only that they experienced their moment of glory in an era in which there was the need to cover rather large spans (those of the sheds which today are part of our archeology industrial) with relatively light roofing layers, arranged on pitched structures.

For this purpose, wooden trusses were less suitable, more expensive for large spans, too heavy for sheds with a thin shell which favors large openings to have as much light as possible inside. Furthermore, the presence of industrial processes could expose wooden structures to a greater fire risk than that of a church. On the other hand, it should be admitted that the typical and valuable essences for wooden trusses, in particular larch, are not so flammable and are highly resistant to fire, while the slender metal structures perhaps do not catch fire, but collapse much sooner due to the heat. due to the fire.

However, the most important factors for the adoption of the metal truss remain the coverable light, the cost, the lightness and its image resulting from calculation and suited to the age of steam, coal, cement and steel. To realize this, just compare the two images: the tie rods of the Barcelona market are almost invisible, the monks on the trusses of the Doge’s Palace in Venice are much bigger than the fire extinguisher.

The Born market in Barcelona: wholesale fruit and vegetable market (1930) – Wikipedia

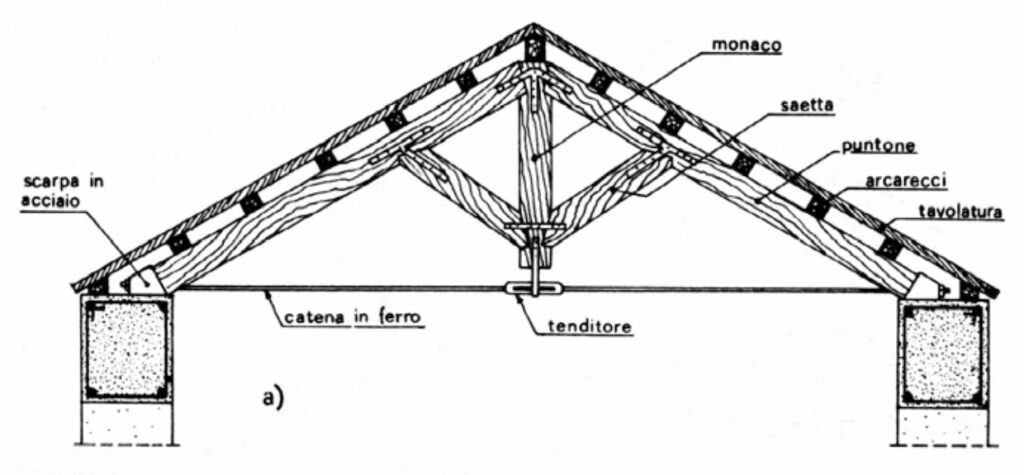

We are therefore witnessing the progressive replacement of the elements of the wooden truss with others in metal, starting with the one that works by traction, the chain, which is also the piece that requires cutting the wooden trunks of greater section and value, despite of a much thinner metal tie rod. This is a progressive functional specialization of components that can guarantee greater resistance with lower dead weights, which is particularly important for extended spans.

Mixed Palladian truss – unibas.it

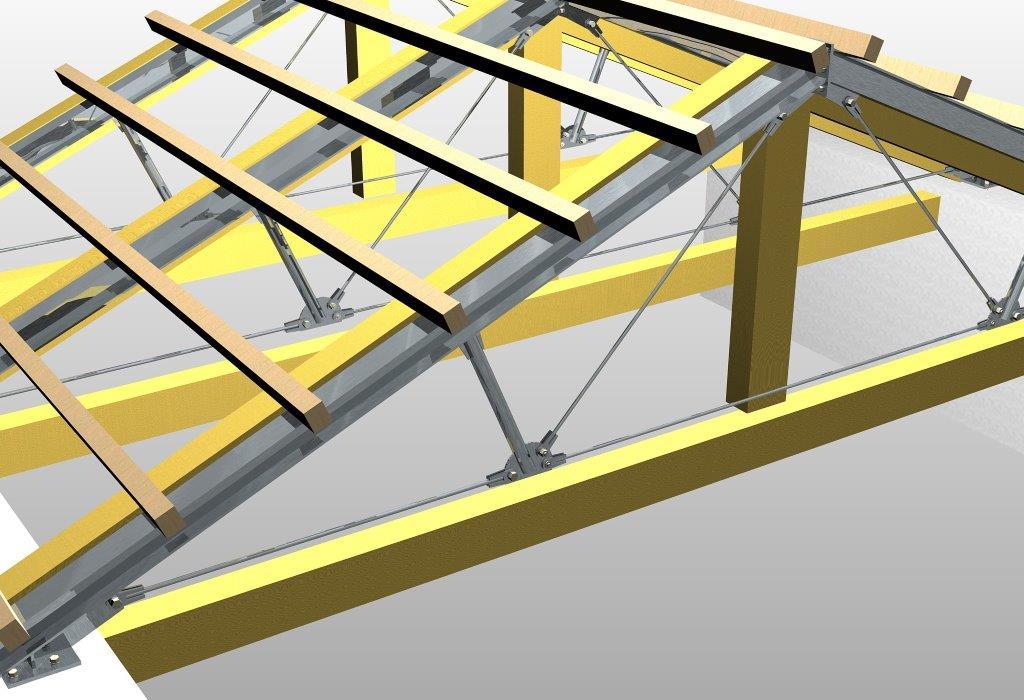

The study of mixed typologies in wood and steel can prove particularly useful in the recovery of wooden roofs where it is necessary to replace some elements, or strengthen the structure as a whole by placing other supports alongside historical elements that maintain a clear distance from the former typological.

Renovation of the roof of the Foglizzo castle – Violetto Ingegneria

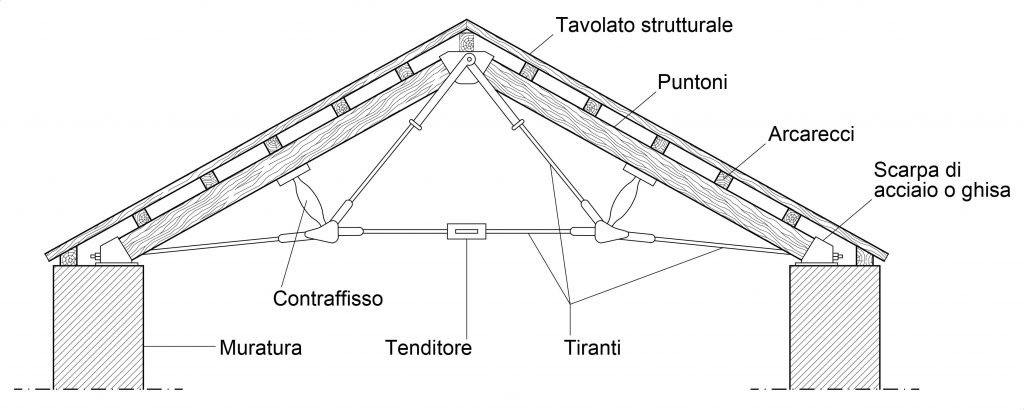

The protagonist of the story about the transition from wooden trusses to metal ones and then to trusses is called Jean-Barthélémy Camille Polonceau (1813 – 1859), a French railway engineer (as well as his father and uncle) who in 1837 developed a system mixed in wood and steel in which a system of metal tie rods replaces saettoni and monk. From this scheme he then arrives at schemes of completely metal trusses which bear his name and which even today we simply identify as Polonceau.

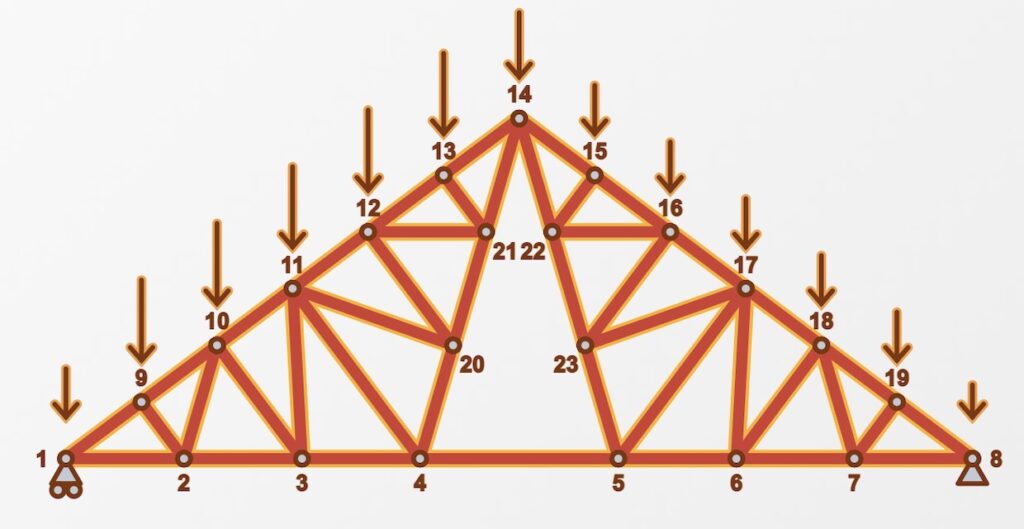

Diagram of a Polonceau truss – ilcapochiave.it

Modern materials guarantee greater durability than wood, especially on knots. The use of cast iron for the compressed elements (the counterfix which replaces the bolt) and steel for those that work in traction (tie rods) highlights even more the different paradigm of the modern construction technique based on calculation, even when continue to use wooden struts, because in that position and with that type of bending load, a steel element would be neither much slender nor much lighter than wood.

Illustrative diagrams of the Polonceau truss – Wikipedia

Polonceau truss static diagram – ilprontuario.com

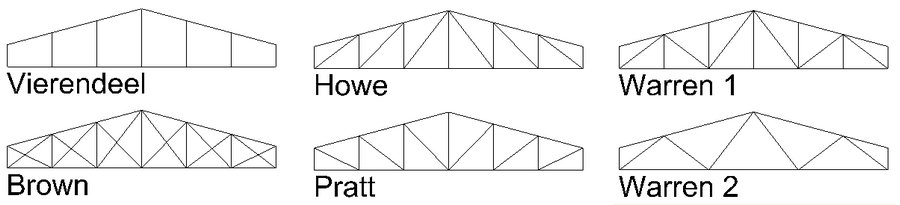

Types of trusses – teknoring.com

The Polonceau may perhaps represent a transition element and in its figure there remain three well-defined vertices within which a stiffening network develops. As well as another example of evolution in mixed structures is that of Amand-Rose Emy, again around the 1840s.

Wooden structure with steel tie rods by Amand-Rose Emy, 1830 – iuav.it

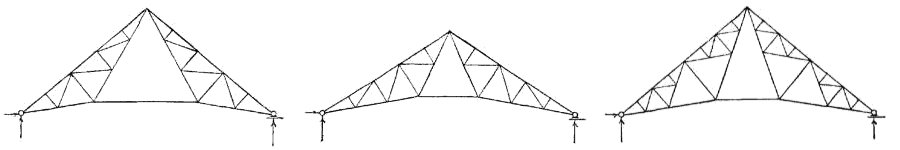

From Polonceau’s inverted V-shaped double strut structures and other experiments on metal and mixed frames, we move on to English-style typologies that end the metamorphosis towards the reticular beam, up to conformations that resemble elongated pentagons rather than triangles .

Types of metal trusses – cadlinews.com

Immagine di copertina: Lightweight Steel Truss System – https://www.roofseal.com.my/