Recycled concrete

Recycled concrete for circular construction

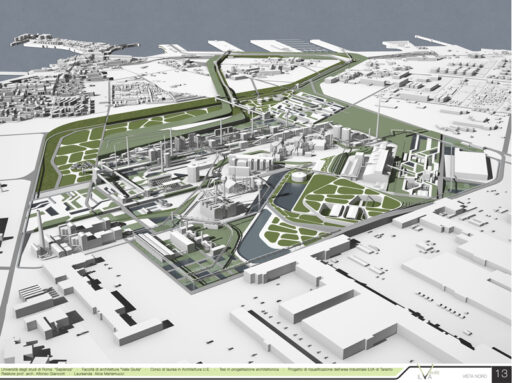

It is now known that the current building sector has a high impact on the environment in terms of pollution and energy consumption. For this reason, a transformation of the area in a green key is increasingly necessary, through the adoption of a circular type of building.

In this regard, if the waste from the demolition of disused buildings were recycled and reconverted for a new use, it would save from an economic and environmental point of view.

An excellent example of this is recovered concrete, a material with numerous potential.

But let’s see now, with these guidelines, what it consists of and what are the uses of this product.

Concrete and recycling

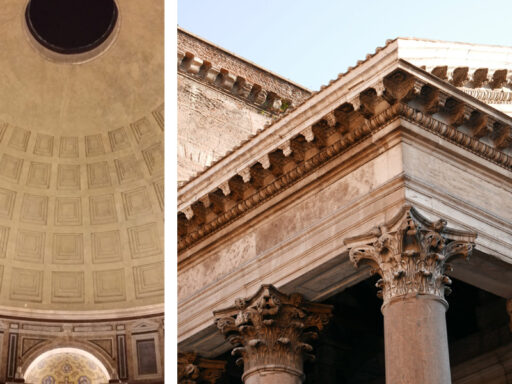

Cement is one of the most used materials in the construction field and its production causes a substantial percentage of carbon dioxide emissions. For this reason, it is necessary to prolong the life cycle and use of this substance, through its recycling.

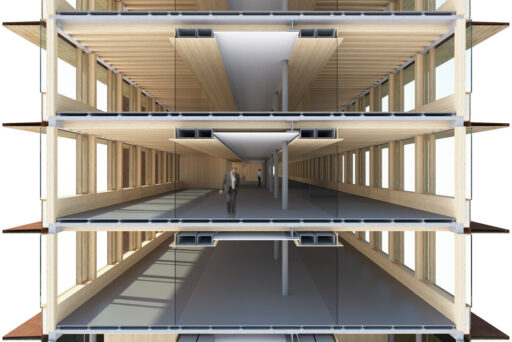

What characterizes the recycled product, compared to that of normal production, is its composition. In fact, it contains cement waste and aggregates originating from demolition, rather than from traditional processes. The percentage of these recycled components and their size determine the diversified use that can be made of this material. It is important to point out that it is a product that is still being studied today and for this reason, that it represents a real challenge for the sector.

However, the recycling activity is very important for the current scenario in which sustainability is now considered an indispensable practice for the future. Even the materials arriving on site must be subject to precise rules and comply with the CAMs.

But what are CAM? From the acronym, these are the minimum environmental criteria, requirements introduced by the Ministry of the Environment and aimed at encouraging more sustainable building activity with less impact from an environmental, economic and social point of view. Other important purposes of these criteria are the increase in energy efficiency and the use of certified materials.

As already mentioned, building materials such as concrete, at the end of their life, are disposed of in landfills and this process, in addition to having a cost, has a significant impact on the environment. For these reasons, it is good to implement a valorisation and give new life to materials that are still potentially useful in the construction sector. An interesting aspect, in the recovery process, concerns the Passport of materials, a real identity card that indicates the peculiarities, the quality standard and the quantity of substances used for the production. One of the main objectives of this document is precisely to encourage the recycling of building materials, according to a circular economy, ensuring greater transparency.

Characteristics and differences from natural concrete

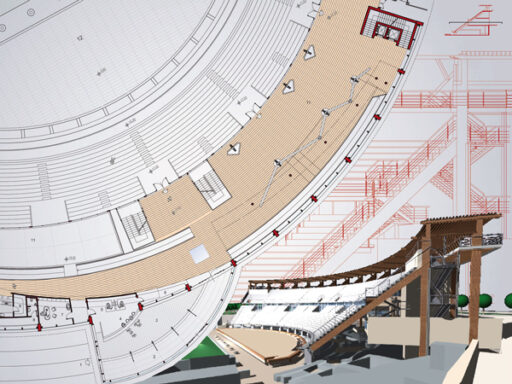

The production of recycled concrete requires some essential steps to guarantee an optimal final product from a qualitative point of view. In fact, it is essential that the materials to be recycled undergo certain processes such as slagging, storage, cooling and crushing. This is followed by a check on the consistency of the material, aimed at ensuring the absence of harmful and polluting substances. Only in this way can recycled concrete obtain the CE mark and be placed on the market. The UNI EN 12457-2 Standard establishes the limit values within which any harmful concentrations must comply, so that they do not represent a danger to people and things.

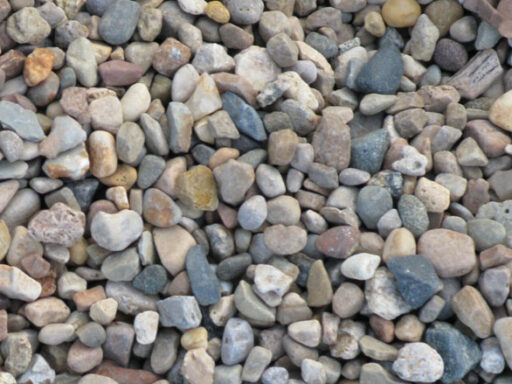

It is important to point out that the materials destined for recycling are heterogeneous and for this reason, that they need careful analysis before being introduced into the recovery process. In fact, glass waste, ceramics, bricks and materials from demolition will be reused to give life to the finished product.

It is therefore clear that this type of substance is less “pure” than that traditionally generated with natural aggregates. However, you can choose to recover only fragments from concrete demolitions. In this way, the final material will be ecological because it is recovered but more homogeneous and with better performance.

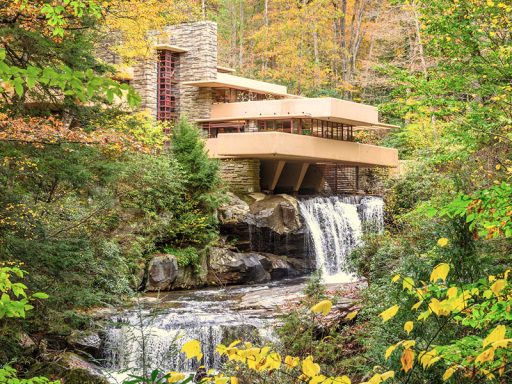

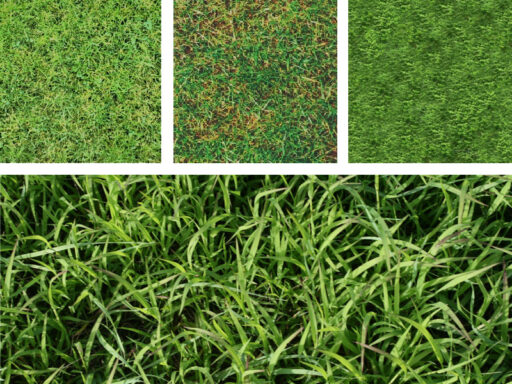

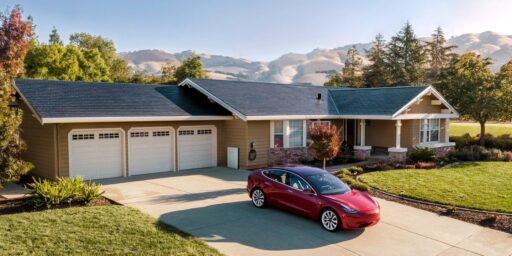

Author photo: ewanvong@gmail.com

But let’s see now what differentiates the concrete obtained through the reuse of demolition components from that coming from traditional processing.

The former is less resistant than the latter from a mechanical point of view. If the concentration of recycled elements is high, the resulting material is less workable and for this reason, it requires a higher quantity of water also due to the greater absorption of the broken particles.

As regards the durability of this type of product over time, to date there are no certain answers but numerous studies are underway to concretely test its durability and to increase it through the possible addition of metallic materials.

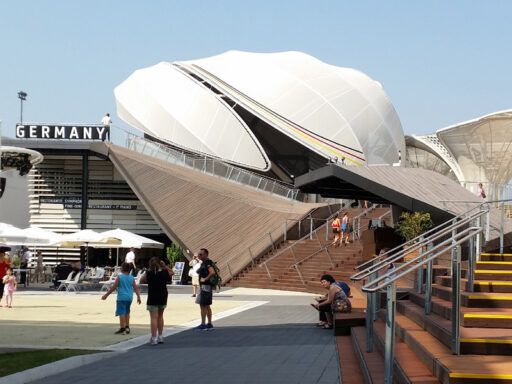

The recovered cement is less versatile than the traditional one and its composition determines the methods of use, since the more heterogeneous it is, the less it will be used in the construction field. They range from noble works, for which a minimum heterogeneity of the particles is essential, to road and filling works, for which less homogeneous components are also allowed. Furthermore, differentiated aggregates will never be used to manufacture structural components.

Hence, the field of application of recycled material is vast and as of today, uncertain and complex. Depending on the compositional characteristics of the recycled concrete, it will be necessary to make informed choices.

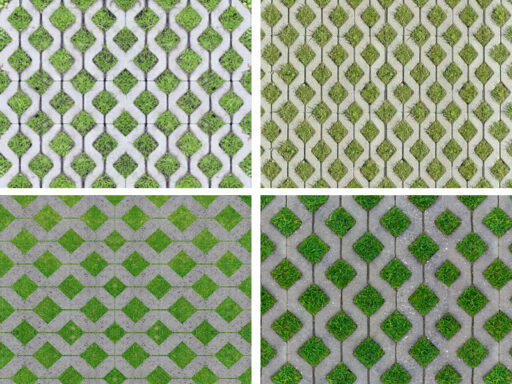

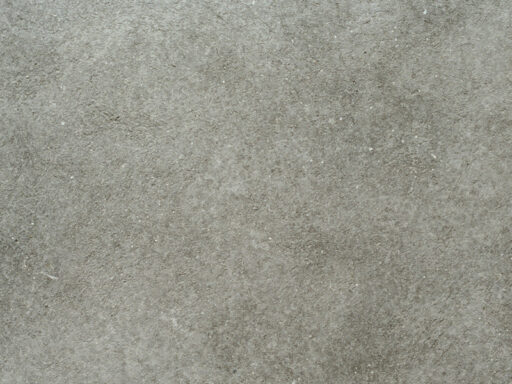

To view some types of concrete see our textures click here

Benefits and legislation

Despite the cement produced from recycling, today, still has some limitations, it is considered a solution with multiple potential. Just think of the numerous advantages it ensures if it is chosen in the construction field.

First of all, the ecological footprint closely linked to its production: the aggregates that compose it, in fact, are waste or materials from the demolition of old buildings. If they are not reused for this purpose, they will end up in landfill resulting in wasted resources, increased pollution and further costs. Linked to this concept, recycled concrete is subject to the now mandatory environmental requirements in the construction sector. It follows that this type of concrete is 100% sustainable, as it respects the environment of today and tomorrow. Furthermore, even from an economic point of view, it is a material with low costs compared to that made up of natural components.

It is important to point out that the final product requires checks from a regulatory point of view. In fact, every recycled substance that will compose it will necessarily have to comply with the relevant laws. The EN 12620 standard establishes that the components, in order to be used, must comply with the requirements of the UNI EN 206-1. The latter provides a table relating to the characteristics of the cement and determines the qualities that the material must possess, in order to ensure the durability of the work for at least ten decades, also in relation to the site where the artefact will be built.

On September 27 of the current year (2022), a new law was introduced which determines the end of the concept of waste in relation to substances that are intended for reuse in the construction sector. However, in order to be re-entered on the market, these must necessarily guarantee the standard required by law. The quantities and concentrations of each individual substance recovered from selective demolition will also be indicated. Furthermore, a recovered material to no longer be considered waste must be destined for specific uses, must satisfy the required technical qualities and guarantee adequate performances. The final product must be required by the current market and must not have any negative effect on the environment and on individual safety.

The future will reveal whether this legislation has contributed substantially to the achievement of a circular economy and an increasingly green construction sector.