The drywall

Number one ally of renovations

Plasterboard is one of the most used materials in construction today, both in the design from scratch and in the interventions on the existing one. More and more users require partition walls and false ceilings, but also furnishing solutions such as plasterboard kitchens. In fact, thanks to the extreme versatility and simple processing, with this material it will be possible to design ad hoc dividing elements and construction components even within already built environments.

So let’s see what the characteristics of plasterboard are and what results its use leads to.

What does plasterboard consist of?

As already mentioned, it is a material widely used in construction, which has its origins in the USA, in the early 1900s. Soon from America, its use spread to northern Europe and later throughout the world. During the 1960s, the material arrived in Italy but it was still necessary to wait some time for its great potential to be discovered.

The plasterboard is a natural product, consisting of a central body in plaster and two sheets of sturdy cardboard, positioned on the two external sides in order to protect it. These are raw materials present in large quantities in nature and for this reason, in addition to representing a sustainable solution, it also boasts a low cost. In industries, the module is processed and obtained through the mixture of gypsum, binders and water. The material is sold in panels that can have variable dimensions. The measurements are chosen according to the specific need and usually the standard length corresponds to 1.20 meters, while the most requested thickness is 13 mm. In addition, thanks to the addition of specific substances, the panel can provide optimized performances from an acoustic and moisture resistance point of view.

Among the many advantages of this material, we find the versatility of use, in fact it can be used in public and private areas, in all indoor environments and for many needs. Furthermore, it is a sustainable and easy to install solution; in fact, it requires less time than traditional building materials and guarantees greater cleaning during the fixing phase.

Drywall and dry mounting

The composition of the plasterboard panel allows to simplify the assembly phase. In fact, it is a modular system that requires a simplified installation but not therefore achievable through the simple do-it-yourself. It is always good to turn to professionals in the sector to obtain an optimal and long-lasting result.

First of all, the plasterboard panel should contain a good thermal insulator such as rock wool or expanded polystyrene. In this way the wall will be more performing and over time will ensure greater comfort for users.

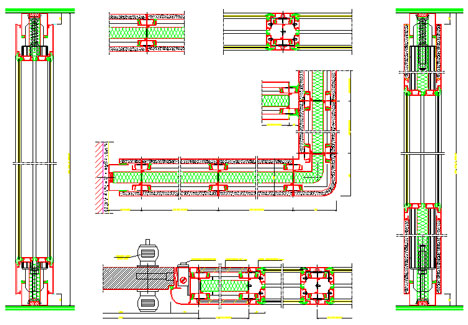

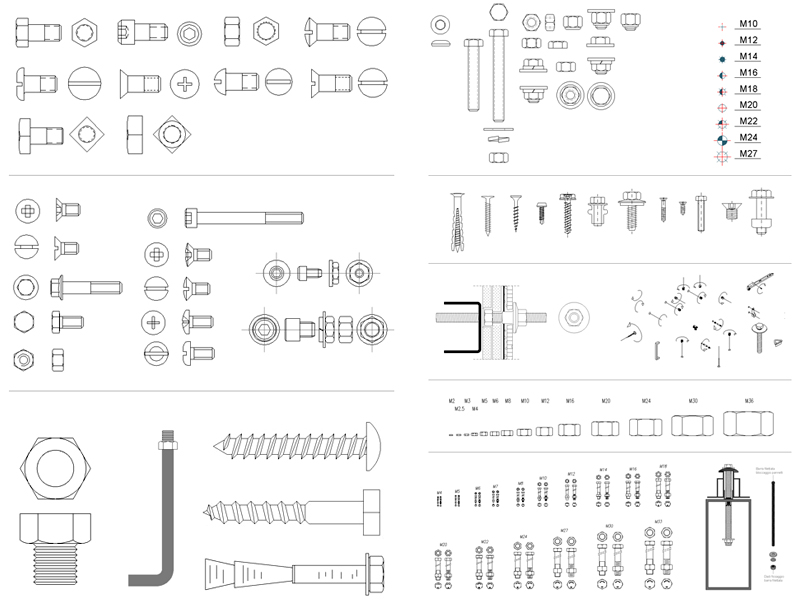

The compositional system of the plasterboard sheets includes two main elements: the actual module and the anchoring structure. The latter consists of galvanized steel elements, which are fixed to the load-bearing walls of the building subject to the intervention. The connection is made thanks to the use of specific metal plugs positioned on the wall or ceiling, depending on the type of solution chosen. Once the frame is anchored, the plasterboard module is welded to it. Sometimes, in the case of suspended ceilings, the panels can be hung through vertical steel elements. As far as the laying between the different slabs is concerned, there must be a connecting mesh, above which the layer of stucco will be applied.

It is therefore clear that assembly is quicker than the usual construction processes that use traditional materials. Times are shortened also thanks to the possibility of hiding the systems inside walls and false ceilings. The yard is also cleaner as each module is prefabricated and therefore ready to be anchored. Finally, in case you want to make changes or eliminate plasterboard elements, the removal is very fast and does not imply damage to the pre-existence as each wall will only be resting on the floor.

In the face of multiple advantages, the only most critical aspect concerns the strength of the plasterboard walls; in fact, these do not withstand strong impacts and if you want to anchor shelves or suspended elements it will be necessary to act with due care.

Types of plasterboard panel

Thanks to the multiplicity of use, typical of plasterboard, it is possible to find on the market solutions designed specifically for different needs. In fact, through the combination of particular materials with the sheet, it will be possible to increase its insulating, acoustic, thermal and fire resistance capabilities. The standard form is the most used and has a white color. To this solution, an insulating layer of rock wool, polystyrene or expanded polyurethane or cork can be added, in order to increase its thermal-acoustic insulation capacity.

If you want to obtain greater resistance to water and humidity, the slab is treated in the production phase, thus becoming a module with reduced water absorption. This is equipped with a green colored outer casing. Such processing is indispensable for drywall in the kitchen and bathroom. If, on the other hand, you want to obtain greater mechanical resistance, you will have to opt for panels with a gypsum and glass or gypsum and wood core. Thanks to the mixture of these fibers, the load carrying capacity and hardness will increase. These solutions are designed for load-bearing false ceilings and particular plasterboard partition walls such as equipped walls.

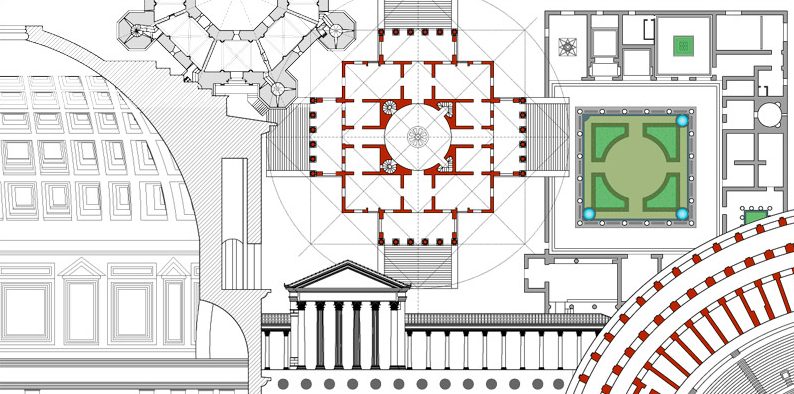

Photo: myinteriordesign.it

A last important solution is represented by the high fire resistance plasterboard modules. Indispensable in public and private buildings, they comply with the REI parameters required by current legislation and are reinforced by materials such as fiberglass and vermiculite. This type of panel is characterized by the pink color.

Most used solutions

It is therefore now clear that plasterboard represents one of the most used materials in the construction field and specifically in interior design. It should also be pointed out that thanks to the high versatility of use, there are many solutions that can meet the needs of the client. For this reason, the material gives the possibility to create new environments with a contemporary flavor. So let’s see what are the most recurrent interventions that make use of plasterboard.

DIVIDING WALLS

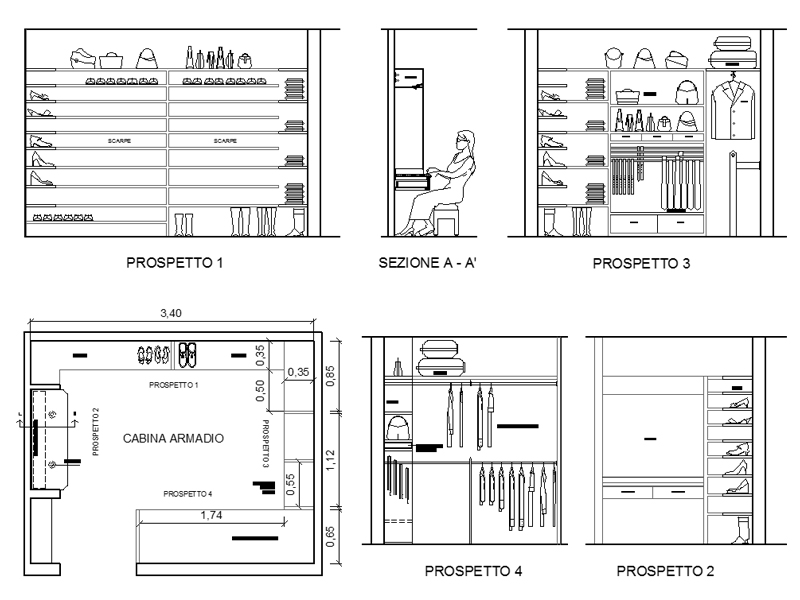

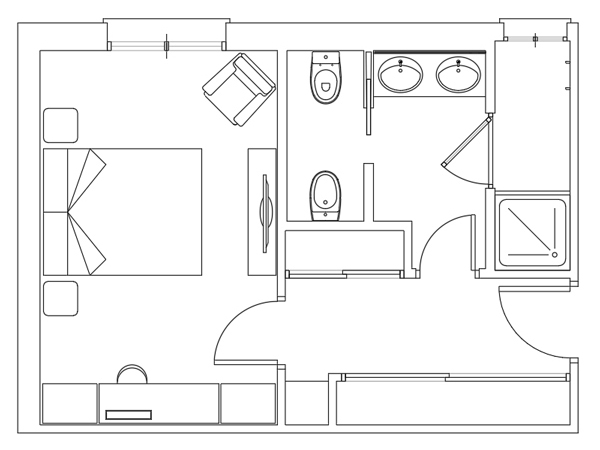

During a renovation, in order to make the spaces more functional, the insertion of new design plasterboard partitions is often envisaged. These elements will be able to divide the environment and create new areas with different intended uses. The greatest advantage consists in obtaining the maximum result with the least waste of space, as the walls are on average 8 – 10 cm thick. In this way you can divide a large open space, create a study corner ensuring greater privacy, create a laundry room in the bathroom or even a plasterboard walk-in closet in the bedroom.

COUNTERWALLS

The counter walls allow you to transform the space by leaning a plasterboard module against an existing wall. One of the most common examples is the plasterboard plate that is placed to cover a door. This is the case of the 1970s residences where there are double entrances side by side and in which what once served as a corridor, today can become a kitchen or a living room. Sometimes, in large spaces it may be convenient to recreate a “filter” area to be used as a closet or walk-in closet, by inserting a plasterboard counterwall. Finally, a very useful solution is represented by the panels placed at a suitable distance from the wall, in order to cover cables and systems.

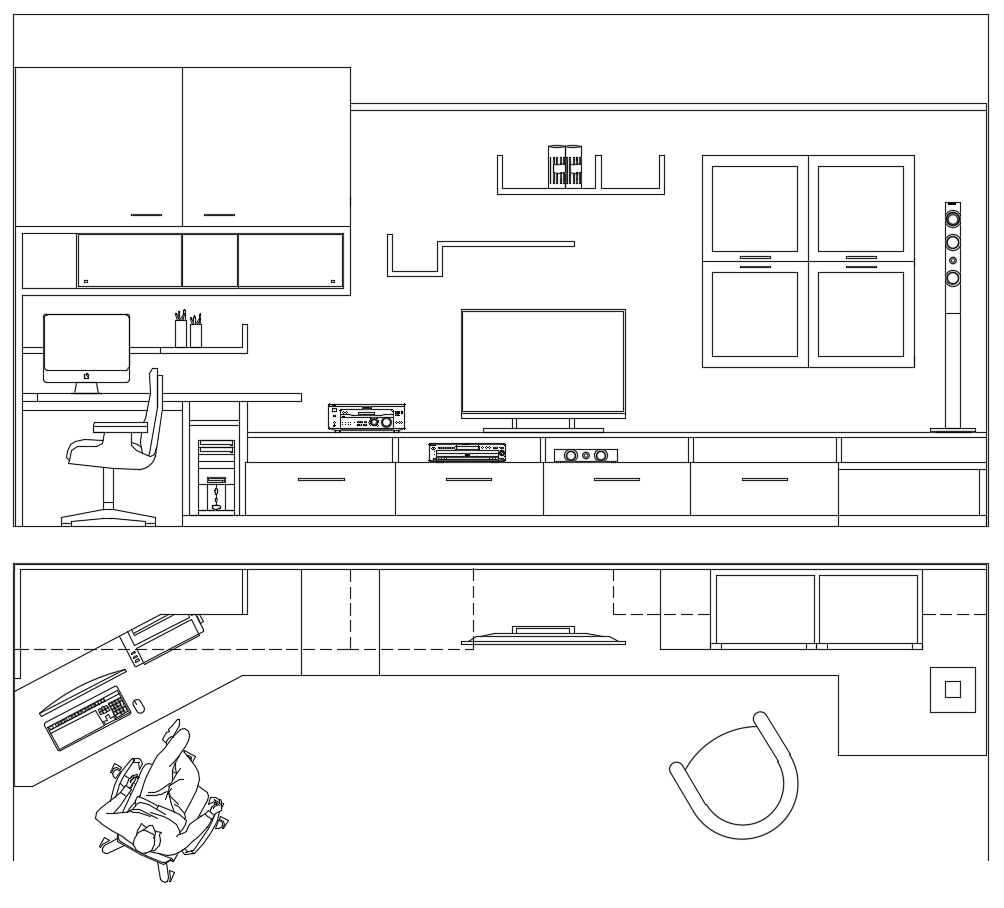

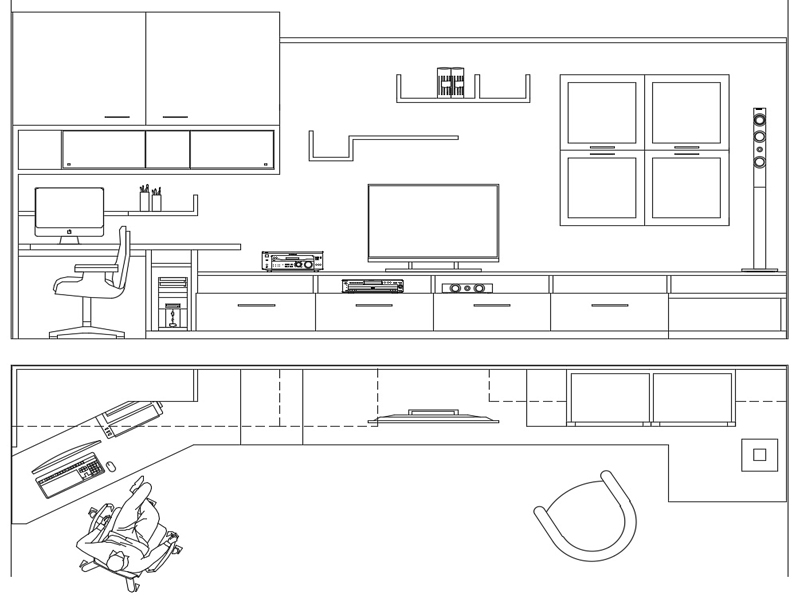

EQUIPPED WALLS

They have met with great success in recent decades, customizing the living rooms with bookcases and open modules. Like the counter-walls, these elements also use plasterboard to meet the most diverse needs. The plus value of these solutions is represented by the wide choice of compositions and the ability to design customized modules, based on the space available and aesthetic tastes.

If you want to learn more, click here

NICHES – COLUMNS – PENINSULA

If the size of the house does not allow a complete exploitation of the space, it is possible to resort to useful and original solutions. For example, the presence of a column, initially, can be interpreted as a constraint but, through the creation of illuminated niches, this element can become a pleasant bookcase. Similarly, niches with shelves and shelves can be obtained almost anywhere and the insertion of plants and ornaments will enhance the compositional ensemble. But the column can also become a luminous element, within which to create ad hoc light cuts. And again, if you are in the presence of an open space, the plasterboard can give life to useful peninsulas and snack tops that will be perfect for combining aesthetics and functionality.

FALSE CEILINGS

The dual purpose of false ceilings is to improve the thermo-acoustic insulation of the environment and to respond to specific needs in the field of lighting. In this way, in addition to being very functional in hiding systems and technical spaces, they can create plays of shapes and lights that will characterize the spaces more. An original solution is that of the design false ceiling in the bedroom, in which mini LEDs can be integrated, in order to emulate a starry sky. The entrance and corridor area can also be enriched by a plasterboard false ceiling with spotlights, useful for creating spectacular light paths.

FURNITURE COMPONENTS

Often, “tailor-made” furniture is manufactured with plasterboard. Very useful in situations where space is limited and where the heights do not allow the choice of standard furniture. In the case of attics and attic rooms it will be possible to design ad hoc kitchens, shelves and furniture. Instead of the bedside tables next to the bed, you can insert comfortable shelves in plasterboard, with a clean and minimal look.

In conclusion, depending on the need, you can opt for plasterboard panels of different thickness, coupled with materials that increase their performance and with a personalized design. The result will not disappoint: there will be many ideas to create unique and original environments!